When customers ask me, “What is a fuel injection system?” I tell them it’s the heart of modern engine performance. A fuel injection system precisely sprays fuel into your engine, ensuring better combustion, improved efficiency, and reduced emissions.

At Arnone’s Car Care, I’ve seen how this advanced system keeps vehicles running reliably while offering a significant boost in power and economy over older carbureted engines.

Fuel Injection System Explained

Think of the fuel injection system as your vehicle’s heart, pumping the exact amount of fuel your engine needs to run smoothly. Unlike the carburetor systems we replaced in the ’90s—which mixed air and fuel mechanically and often imperfectly—modern fuel injection systems precisely control how fuel is delivered to each cylinder over thousands of cycles every minute.

How It Works? A fuel injector is essentially an electronic valve that sprays fuel in a high-pressure mist into the intake manifold or directly into the combustion chamber. The atomization of the fuel ensures better combustion, which translates to increased fuel efficiency and reduced emissions.

There are several types of fuel injection systems, but the most common are:

- Throttle Body Injection (TBI): This system uses a single injector in a throttle-like housing, spraying fuel for all cylinders. It’s simpler but less precise.

- Multi-Point Fuel Injection (MPFI): Each cylinder gets its own injector, improving fuel distribution.

- Direct Injection: Fuel is delivered directly into the combustion chamber for advanced precision. These systems improve power and economy but can require more frequent maintenance.

Real Customer Challenges

Just last week, a customer with a 2016 Ford Explorer came in complaining of poor acceleration and low efficiency. A fuel injection system cleaning solved the issue. Over time, dirt, carbon deposits, and contaminants clog the injectors. When this happens, they either struggle to spray the precise amount of fuel required or spray unevenly, leading to poor performance.

At Arnone’s, we use industrial-grade fuel injection system cleaners administered through specialized equipment. This process, combined with manually inspecting each injector’s spray pattern, restores the system to optimal working order. These services generally take about two hours and can often save customers from more costly injector replacements, which can run upwards of $1,000 or more.

When working with high-quality engine components, ensuring they are clean and operating efficiently also complements other systems in your vehicle. For instance, a properly functioning car cooling system keeps your engine at the right temperature, making complex fuel systems work their best.

The Importance of Fuel Injection System Service and Maintenance

For decades, customers have trusted me to keep their vehicles road-ready, and I can’t stress enough how regular maintenance saves money in the long run. Here’s what I recommend:

- Regular Cleaning: A fuel injection system cleaning every 30,000 miles or during annual inspections can prevent buildup. You might not notice a gradual loss of efficiency, but cleaning can restore lost performance.

- Quality Fuel: Using high-quality gasoline with detergents can minimize injector clogging. Some premium fuels even contain additives designed to keep injectors clean.

- Fuel Filters: Replace the fuel filter as part of your maintenance schedule. A clogged filter can restrict the fuel flow to the injectors, forcing them to work harder.

- Diagnostic Checks: Engine warning lights or detections of hesitation could be linked to the injection system. At Arnone’s, we use advanced diagnostic tools to identify problems early.

Along with injector services, maintaining other key components, like the timing belt, is essential. The timing belt plays a critical role in synchronizing engine operations, ensuring the fuel system is timed correctly with engine cycles.

The Technology Behind Today’s Fuel Systems

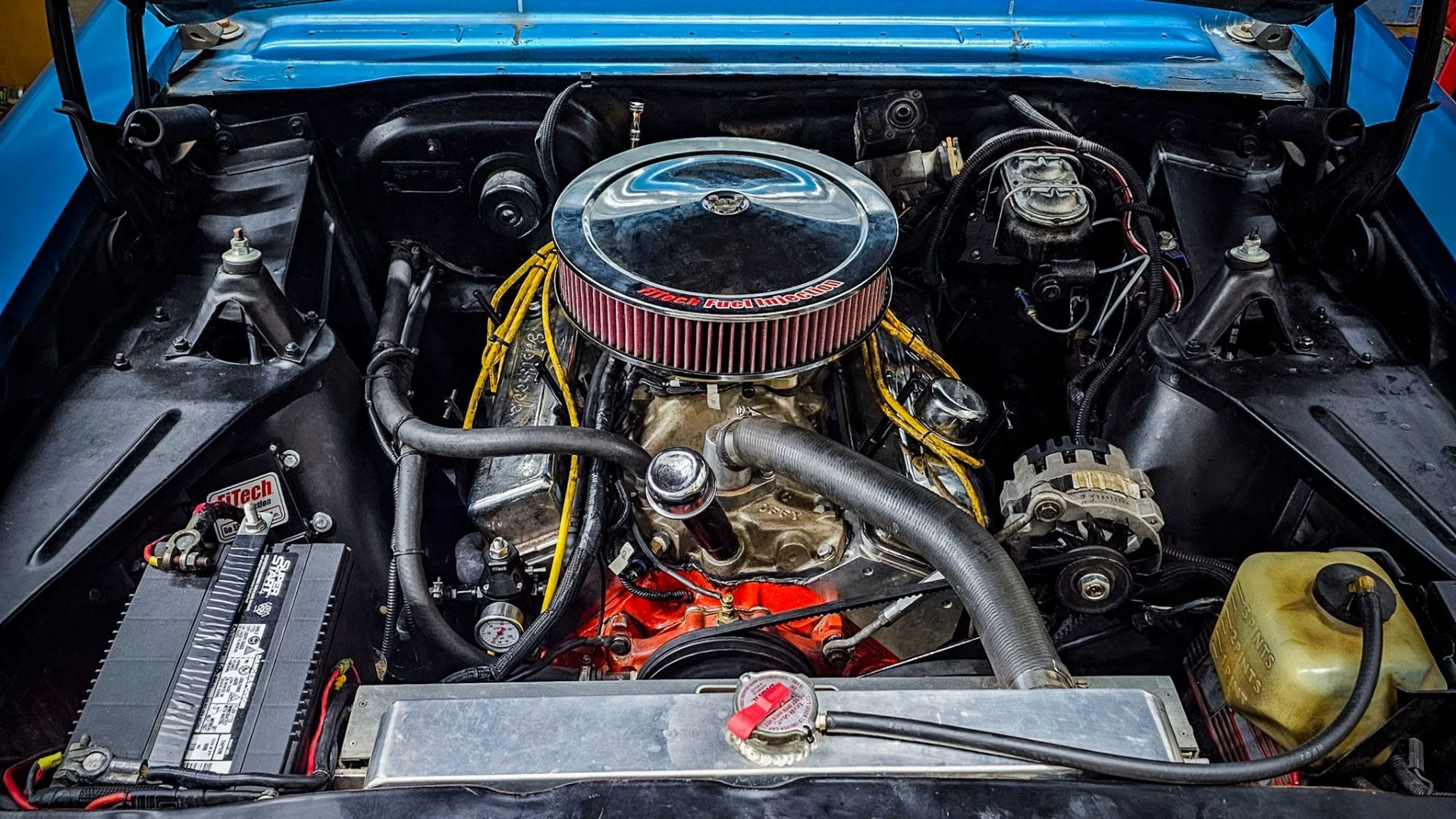

If you’re a car enthusiast, the fuel injection system diagram is one of the most fascinating pieces of engineering. The components include:

- Fuel Pump: Pressurizes fuel from the gas tank.

- Fuel Rail: Delivers pressurized fuel to each injector.

- Injectors: These tiny valves atomize the fuel into a fine mist.

- Engine Control Unit (ECU): This is the system’s brain, using sensors to calculate how much fuel is needed based on throttle input, oxygen content in exhaust, engine temperature, and more.

Fuel injectors operate in milliseconds, opening and closing at speeds of up to 10 times per second. With modern direct injection systems, fuel is sprayed at pressures as high as 2,500 psi, delivering unparalleled precision. However, this complexity requires advanced expertise to service.

Practical Advice for Owners

Here’s some practical advice I share with customers:

- If your car hesitates during acceleration or has trouble starting, it could be a sign of clogged injectors. Don’t ignore it.

- Look out for dips in fuel efficiency. A sudden drop from, say, 28 MPG to 24 MPG can indicate injector issues.

- Drive your car for occasional long trips. Engines operating at higher loads can naturally burn off some carbon buildup.

Some customers also ask about DIY fuel injection system cleaner products you can pour into the gas tank. While these can help between professional cleanings, they’re not a substitute for the equipment and know-how at a repair shop like ours.

If you’ve noticed poor engine performance or low throttle response, it could also be tied to more significant concerns. My advice? Don’t wait until you’re considering an expensive engine rebuild down the line to tackle smaller problems today.

Why It Matters?

When cars were primarily carbureted, mechanics often had to strike a balance between performance and efficiency. With fuel injection systems, however, every drop of fuel is atomized to power your vehicle without waste. This is one reason why modern engines regularly surpass 200,000 miles with proper care. Routine services like injector cleaning, diagnostics, and inspections will keep your engine running for years to come.

Credit IG – thedailymisfire

My Commitment to You

At Arnone’s Car Care, we treat every car we service like it’s our own. I understand how valuable your vehicle is to your day-to-day life. Whether it’s cleaning a fuel injection system for the first time or replacing a failing injector, I provide honest, reliable service that ensures your car performs at its peak. If you’ve never had your injectors checked or cleaned, reach out to me. Together, we’ll keep your car running like the day you drove it off the lot.

Every week, I’m reminded why I love what I do. Whether it’s an old carbureted classic or a cutting-edge direct-injection engine, each system tells its own story. And at Arnone’s, we make sure every story ends with a satisfied customer driving away safely.

If you’re dealing with fuel-related issues or engine concerns, don’t hesitate to explore how problems like engine stalling may also be linked to your fuel system. Want to learn more or schedule an appointment? Call us today, and I’ll be happy to inspect your fuel system myself!

Fast, Reliable Diagnostics Service for Your Engine

If your vehicle is showing signs of engine trouble, don’t delay! Call the experts at Arnone’s Car Care in Kansas City for reliable diagnostics and quality repairs. Our dedicated mechanics will identify the issue quickly and work to get your car back on the road safely. Dial (816) 471-8560 to schedule an appointment today. Trust us for the honest, dependable service that keeps your car running smoothly.