Your tires are your vehicle’s only connection to the road, making tire health crucial for your safety and driving performance. Most drivers wait until a tire goes completely flat before paying attention, but recognizing early warning signs can prevent dangerous blowouts and costly emergency repairs.

By understanding tire sizes and recognizing issues early on, you can avoid major problems. This comprehensive guide will help you identify common tire problems, understand what causes them, and determine when replacement is necessary. By learning these diagnostic skills, you’ll drive with confidence while extending your tires’ lifespan and protecting your investment.

Understanding Tire Wear Patterns

Tire wear patterns can provide important insights into the overall health of your vehicle and help you identify potential issues with alignment, pressure, or suspension. Understanding these patterns allows you to address problems early, ensuring better performance, safety, and longer-lasting tires.

1. Uneven Tire Wear

Uneven tire wear occurs when different sections of your tire tread wear at different rates, creating an irregular surface pattern. This dangerous condition reduces your tire’s contact patch with the road, leading to poor handling and longer stopping distances.

What to look for: Check for tread depth variations across the tire width. Use a penny test by inserting Lincoln’s head upside down into the tread grooves. If you can see the top of Lincoln’s head in some areas but not others, you have uneven wear.

Common causes:

- Improper wheel alignment

- Incorrect tire pressure

- Suspension component problems

- Lack of regular tire rotation

When to replace: Replace tires immediately if tread depth varies by more than 2/32 of an inch across the tire surface. Continuing to drive on unevenly worn tires compromises your safety and can cause handling issues.

2. Center Wear Patterns

Center wear appears as excessive tread loss down the middle of your tire while the edges remain relatively intact. This pattern indicates chronic overinflation, where excessive air pressure causes the tire to balloon outward.

Prevention: Check your tire pressure monthly using a reliable gauge. Refer to the placard on your driver’s side door jamb for the correct pressure, not the maximum pressure listed on the tire sidewall.

Repair options: If caught early, simply adjusting to proper tire pressure can prevent further center wear. However, if the center tread is significantly worn compared to the edges, replacement is necessary.

3. Edge Wear Issues

Edge wear manifests as excessive tread loss on either the inner or outer edges of your tire. This pattern typically indicates alignment problems, specifically incorrect camber or toe settings.

Diagnostic tip: Run your hand across the tire tread. If one edge feels sharper or more worn than the other, you likely have an alignment issue requiring professional attention.

Solution: Have your wheel alignment checked and corrected by a qualified technician. If the edge wear is severe, tire replacement will be necessary even after fixing the alignment problem.

Recognizing Audible Warning Signs

Audible warning signs from your tires, such as unusual noises that change with speed, can signal underlying issues like tread wear or internal damage. Identifying and addressing these sounds early can help prevent further damage and ensure your safety on the road.

Noise When Driving

Tire noise that increases with vehicle speed often indicates tread wear issues or internal tire damage. Unlike road noise, tire-related sounds will vary directly with your speed and may change when turning.

How to identify: Turn off your radio and roll down your windows while driving at various speeds. Listen for humming, roaring, or rhythmic thumping sounds that correlate with wheel rotation.

Underlying causes:

- Worn tread blocks creating irregular contact surfaces

- Internal belt separation

- Cupping or scalloping wear patterns

Action required: Have your tires professionally inspected if you notice new or increasing noise levels. Continuing to drive on noisy tires can lead to sudden failure.

Identifying Physical Tire Damage

Physical tire damage, such as bulges, cracks, bubbles, or blisters, can compromise your tire’s structural integrity and pose serious safety risks. Identifying these issues early and replacing damaged tires is crucial to prevent blowouts and ensure safe driving.

1. Bulges or Cracks

Bulges appear as balloon-like protrusions on your tire’s sidewall, while cracks manifest as visible splits in the rubber surface. Both conditions indicate structural integrity problems that require immediate attention.

- Bulge formation: Occurs when internal tire components separate, allowing air to push against weakened areas of the sidewall. This often happens after impact with potholes, curbs, or debris.

- Crack development: Results from rubber deterioration due to age, UV exposure, extreme temperatures, or chemical exposure. Cracks typically appear first on sidewalls before spreading to tread areas.

- Safety concern: Both bulges and cracks represent potential blowout risks. Replace any tire showing these symptoms immediately, regardless of remaining tread depth.

2. Bubbles or Blisters

Bubbles and blisters indicate internal tire damage where the various layers have separated, creating air pockets beneath the surface. These defects most commonly occur after striking curbs or other obstacles.

Visual inspection: Look for raised areas that weren’t present when the tire was new. These may appear as small bumps or larger balloon-like sections on either the sidewall or tread area.

Immediate replacement: Any tire with bubbles or blisters should be replaced immediately. These represent weak points that can lead to catastrophic failure without warning.

Air Pressure-Related Problems

Air pressure-related problems, such as frequent pressure loss or the activation of the low tire-pressure light, can signal underlying issues like punctures, valve stem wear, or sensor malfunctions. Regular tire pressure checks and timely professional inspections can help address these problems and prevent further damage.

1. Frequent Air Pressure Loss

Tires naturally lose air pressure over time, typically 1-2 PSI per month. However, frequent pressure loss indicates underlying problems that require attention.

Common causes:

Here are some common causes of tires losing air pressure over time:

- Small punctures from nails or screws

- Valve stem deterioration

- Bead seal problems

- Wheel porosity or corrosion

Diagnostic steps: Check tire pressure weekly for several weeks. If a tire consistently loses more than 2-3 PSI per week, have it professionally inspected for leaks.

Repair possibilities: Small punctures in the tread area can often be repaired with plug-patch combinations. However, sidewall punctures and valve stem issues typically require tire replacement.

2. Low Tire-Pressure Light Activation

Modern vehicles use Tire Pressure Monitoring Systems (TPMS) that alert you to significant pressure drops. However, this light can also indicate sensor problems or seasonal pressure changes.

Temperature effects: Tire pressure drops approximately 1 PSI for every 10-degree temperature decrease. Cold weather can trigger TPMS warnings even with healthy tires.

Troubleshooting: Check all tires with a manual gauge when the TPMS light activates. If pressures are correct, you may have a faulty sensor requiring professional diagnosis.

Handling and Performance Issues

Handling and performance issues, such as difficulty turning the steering wheel or vehicle vibrations at higher speeds, can be caused by tire problems like low pressure, damage, or imbalance. Addressing these symptoms promptly through tire pressure checks and professional inspections can help ensure smooth handling and prevent further complications.

Hard-to-Turn Tires

Steering difficulty often stems from low tire pressure, which increases rolling resistance and makes the steering wheel harder to turn. This condition mimics trying to pedal a bicycle with flat tires.

Primary causes:

- Severely underinflated tires

- Power steering system problems

- Worn suspension components

- Belt slippage

Immediate action: Check tire pressure first, as this is the most common and easily correctable cause. If pressures are normal, have your power steering system and suspension components inspected.

Vehicle Vibrations

Tire-related vibrations typically occur at highway speeds and may worsen with increased velocity. These sensations can indicate several tire problems requiring professional attention.

Vibration sources:

- Out-of-balance wheels

- Internal tire damage

- Irregular wear patterns

- Bent wheels from impact damage

Speed correlation: Tire-related vibrations usually begin around 45-50 mph and intensify at higher speeds. Brake-related vibrations occur primarily during braking.

Age-Related Tire Deterioration

As tires age, the rubber compounds break down, leading to dry rot and cracks, even if the tread depth seems fine. This can increase the risk of tire failure, making regular inspection and timely replacement essential for safety.

Dry Rot Development

Dry rot occurs when tire rubber loses flexibility due to age, UV exposure, and environmental factors. This condition makes tires prone to cracking and sudden failure, regardless of remaining tread depth.

Visual signs:

- Small cracks in sidewall rubber

- Tread separation from the tire body

- Brittle, inflexible rubber surfaces

- Exposed cord or fabric layers

Prevention strategies:

- Park in shaded areas when possible

- Use tire covers during long-term storage

- Apply UV protectant products regularly

- Keep tires clean and properly inflated

Replacement timeline: Most tire manufacturers recommend replacement after six years, regardless of tread depth. Tires older than ten years should never be used, even if they appear serviceable.

General Tire Age Considerations

Tire age affects safety even when tread depth appears adequate. The rubber compounds used in tire manufacturing gradually deteriorate over time, reducing performance and increasing failure risk.

Age determination: Check the DOT code on your tire sidewall. The last four digits indicate the week and year of manufacture (e.g., 2319 means the 23rd week of 2019).

Replacement guidelines:

- Replace tires after 6-10 years depending on use and storage conditions

- High-performance and low-profile tires may require earlier replacement

- Climate and driving conditions affect aging rates

Advanced Wear Pattern Analysis

Advanced wear patterns, such as cupping, feather-edge wear, and premature bald spots, can provide valuable insights into underlying issues with your vehicle’s alignment, suspension, or driving habits. Understanding and addressing these patterns early can save you money and improve overall vehicle performance.

Irregular Tread Wear

Irregular wear patterns create specific symptoms that help diagnose underlying vehicle problems. Understanding these patterns can save money by addressing root causes rather than just replacing tires.

Cupping or scalloping: Appears as diagonal wear patterns across the tread surface, creating a wavy appearance. This typically indicates worn shock absorbers or struts.

Feather-edge wear: Creates sharp edges on one side of tread blocks while the other side remains rounded. This pattern suggests incorrect toe alignment settings.

Flat spots: Develop when tires lock up during hard braking or sit stationary for extended periods. These create vibrations and noise during driving.

Premature Tire Balding

Rapid tread wear that causes tires to become bald prematurely usually results from incorrect tire pressure, aggressive driving habits, or mechanical problems.

Contributing factors:

- Chronic underinflation increases sidewall flexing and heat buildup

- Overloading vehicles beyond tire capacity ratings

- Hard acceleration, braking, and cornering

- Worn suspension components

Prevention methods:

- Maintain proper tire pressure consistently

- Rotate tires every 5,000-8,000 miles

- Avoid aggressive driving behaviors

- Address suspension problems promptly

Sidewall Damage Assessment

Sidewall damage is a serious concern, as it compromises the tire’s structural integrity and safety. Even minor cuts or tears can lead to catastrophic failures, so any visible damage should be assessed by a professional and replaced if necessary.

Critical Sidewall Issues

Sidewall damage requires immediate attention because these areas experience the highest stress during driving. Unlike tread area damage, sidewall problems rarely allow for safe repair.

Damage types:

- Impact cuts from road debris

- Punctures from sharp objects

- Tears from over-deflection

- Gouges from curb contact

Assessment criteria: Any sidewall damage that exposes internal cords or penetrates through the outer rubber layer requires immediate tire replacement.

Professional evaluation: Have questionable sidewall damage assessed by a tire professional. They can determine whether minor surface damage poses safety risks.

Prevention and Maintenance Strategies

Regular tire inspections and professional maintenance are essential for extending tire life and ensuring optimal performance. By establishing a routine for checking tire pressure, tread depth, and condition, along with timely professional services like rotations and alignments, you can prevent costly replacements and enhance safety.

Regular Inspection Routines

Establish monthly tire inspection habits to catch problems early. Visual inspections take only a few minutes but can prevent dangerous situations and expensive replacements.

Monthly checklist:

- Check tire pressure when tires are cold

- Inspect sidewalls for cracks, bulges, or punctures

- Examine tread depth using the penny test

- Look for foreign objects embedded in treads

- Check valve stem caps and condition

Documentation: Keep records of tire pressure readings and any observed changes. This information helps identify slow leaks and pressure loss patterns.

Professional Maintenance Schedule

Regular professional tire service extends tire life and maintains optimal performance. Establish relationships with qualified tire service providers in your area.

Service intervals:

- Tire rotation every 5,000-8,000 miles

- Wheel balancing when vibrations develop

- Alignment checks annually or after impact damage

- Pressure monitoring system service as needed

Cost considerations: Regular maintenance costs significantly less than premature tire replacement. Most tire service packages offer rotation and balancing at reasonable rates.

When Replacement Becomes Necessary?

Tire replacement becomes necessary when critical issues, like sidewall bulges, exposed cords, or tread depth below 2/32 inch, compromise safety. Additionally, economic factors, such as uneven wear or repair costs approaching replacement, may also warrant timely tire replacement to ensure vehicle performance and safety.

Safety-Critical Situations

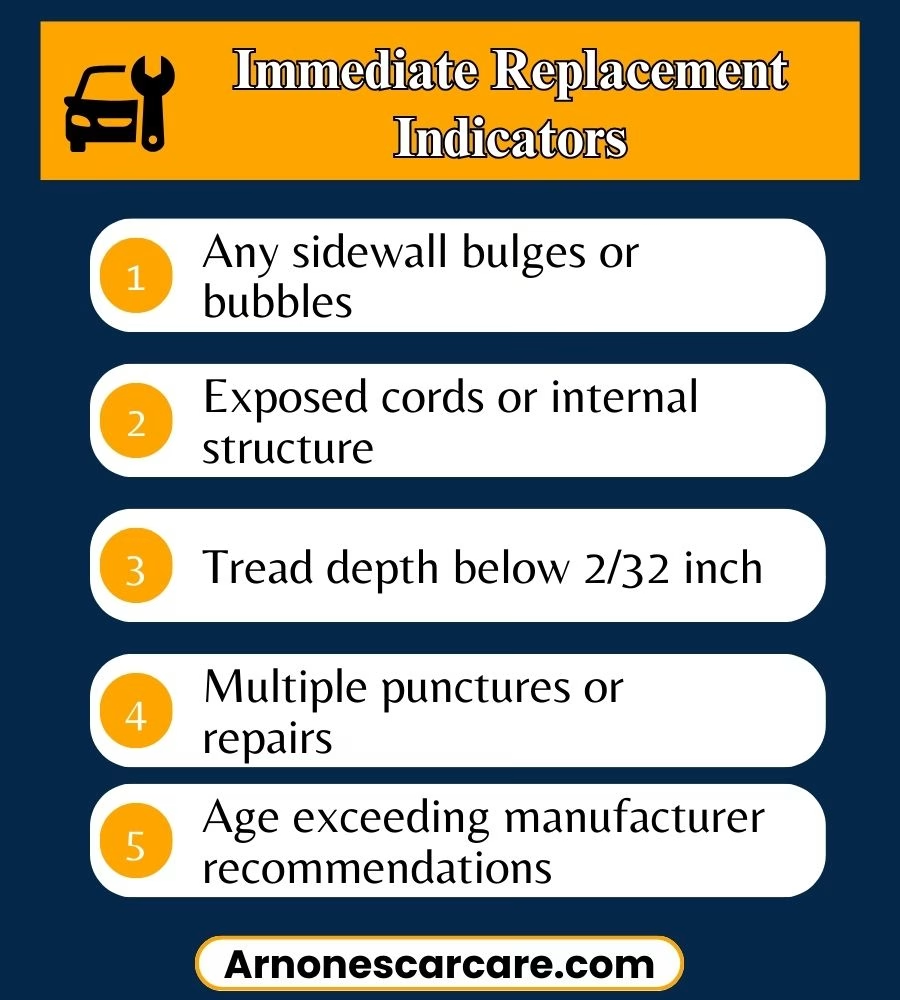

Certain tire conditions require immediate replacement regardless of cost or convenience. Continuing to drive on compromised tires risks catastrophic failure and serious accidents.

Immediate replacement indicators:

- Any sidewall bulges or bubbles

- Exposed cords or internal structure

- Tread depth below 2/32 inch

- Multiple punctures or repairs

- Age exceeding manufacturer recommendations

Emergency procedures: If you discover critical tire damage while traveling, reduce speed immediately and seek professional service. Don’t attempt long-distance driving on compromised tires.

Economic Replacement Decisions

Sometimes tire replacement makes financial sense even when tires aren’t completely worn out. Consider the total cost of ownership when making replacement decisions.

Replacement scenarios:

- Two tires worn significantly more than others

- Repair costs approaching replacement costs

- Seasonal tire changes

- Vehicle handling problems affecting other tires

Budget planning: Set aside funds for tire replacement based on your driving patterns and tire quality. Higher-quality tires often provide better value through longer service life.

Conclusion

Regular tire inspections and maintenance are essential for both your safety and maximizing your tire investment. By learning basic diagnostic techniques, you can detect issues early and decide whether to repair or replace your tires. Tires are a critical part of your vehicle’s safety, so it’s important to seek professional help if you’re uncertain about their condition.

Professional inspections are a small cost compared to the potential risks of tire failure. Start today by inspecting your tires, noting their condition, and setting up a routine maintenance schedule. This proactive approach will ensure optimal tire performance and safety for years to come. For tire repair service, visit our specialized service page for more details.

FAQs

Q. How often should I check my tire pressure?

You should check your tire pressure at least once a month and before long trips. Ensure the tires are cold for accurate readings.

Q. What is the penny test for tires?

The penny test involves inserting a penny into the tire tread with Lincoln’s head facing down. If you can see the top of his head, it’s time to replace the tire.

Q. Can I repair a tire with sidewall damage?

No, sidewall damage cannot be safely repaired. Any cuts, tears, or punctures in the sidewall require immediate tire replacement.

Q. How do I know when my tire is beyond repair?

Tires with sidewall bulges, exposed cords, or tread wear below 2/32 inch need replacement immediately for safety.

Q. What causes uneven tire wear?

Uneven tire wear is often caused by improper alignment, incorrect tire pressure, or suspension issues. Regular tire rotation can help prevent it.